Choosing the right RF filter is crucial to achieving optimal system performance, but it’s rarely...

A Step-by-Step Guide to Designing High Pass Filters for RF Systems

The development of microwave filter theories and practices in the 1930s laid the foundation for modern RF systems. These advancements, driven by the needs of military and aerospace communication, enabled precise frequency control and enhanced signal processing, paving the way for today's sophisticated RF technologies.

Among the most indispensable components in RF systems are high pass filters. These small yet powerful devices block unwanted low-frequency noise while allowing higher frequencies to pass through with clarity.

While RF technology has been standardized over the years, the methods used to design high pass filters can differ significantly depending on application requirements, performance criteria, and several trade-offs. At Q Microwave, we specialize in designing high pass filters that meet the most rigorous performance standards. Our expertise lies in combining decades of engineering experience with state-of-the-art manufacturing processes to deliver filters made to spec. Whether it’s minimizing insertion loss, selecting the ideal topology, or balancing performance trade-offs, we approach every project with precision and care.

How do you design a high pass filter? In this guide, you’ll get a practical, step-by-step design process, from understanding the fundamentals to optimizing high pass filter performance. We’ll also cover real-world considerations such as material choices, manufacturing constraints, and testing methods to guide you in designing filters that will meet your rigorous project parameters.

A Quick Overview of High Pass Filters

In RF systems, there are three main types of filters that serve various purposes: bandpass filters, lowpass filters, and high pass filters. Bandpass filters allow a specific range of frequencies to pass through while blocking everything outside that range. Meanwhile, lowpass filters let only low frequencies through while blocking the high ones. High pass filters, as you’d expect, do the opposite of lowpass filters, letting high frequencies pass and block low-frequency signals.

High pass filters are crucial for filtering out unwanted low-frequency noise or interference, making sure your system focuses on the relevant frequencies. The concept is pretty straightforward, especially when you’ve been designing RF systems for a while.

But it gets interesting when you consider what various high pass filter materials and design procedures actually do for your RF system. The trick is that no single filter works perfectly for every RF use case. Custom designs are often the go-to solution to meet specific parameters.

How to Design a High Pass Filter for RF Systems

Designing high pass filters for RF systems requires a deep understanding of both the theoretical and practical aspects of microwave engineering. Q Microwave has been designing and manufacturing off-the-shelf and custom high pass filters for over 25 years. We continuously refine our design and manufacturing process, work with top vendors to source the highest-quality materials, and consistently meet MIL standard parameters.

It’s rare for microwave filter manufacturers to share the behind-the-scenes process of designing high-performance filters, as most just focus on delivering them on time. However, Q Microwave is eager to share our process to help you make informed decisions.

Step 1: Determine Project Requirements

RF engineers and manufacturers must collaborate closely to fully understand the project's specific design requirements.

Once the parameters are set, the appropriate materials and components for the high pass filter are determined. The process includes selecting the right resonators (inductors and capacitors for tuning), choosing the best form factor, and addressing factors like power handling and frequency range.

Step 2: Develop the Initial Design

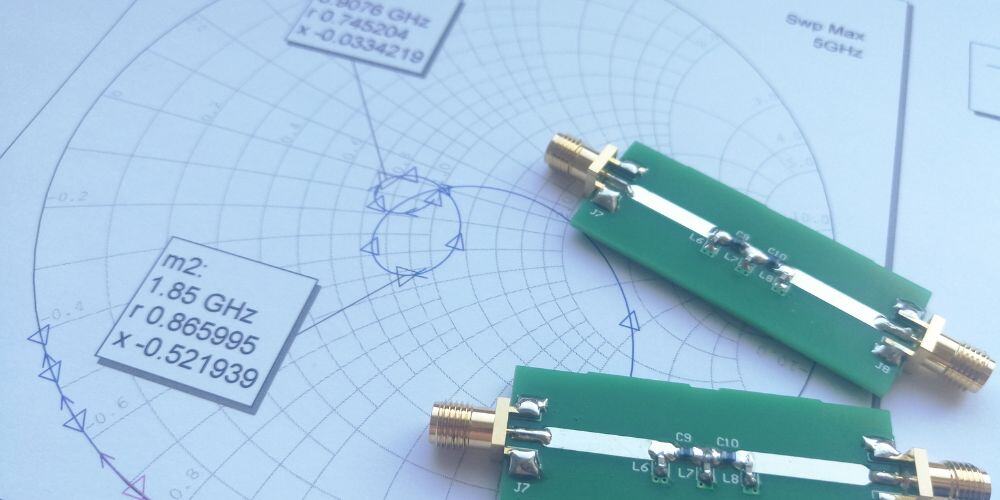

The engineering team creates the initial schematic of the high pass filter and simulates the final product. They also provide an S2P file that outlines the filter's frequency response.

Filter designs and simulations are performed using simulation software tools, high pass filter calculators, and design platforms such as AWR Microwave Office. Equipment such as VNAs, signal analyzers, spectrum analyzers, pulse generators, power meters, temperature ovens, and even liquid nitrogen may be utilized when required to test project specifications.

Step 3: Provide Preliminary Quotes

“Cost is a key consideration for engineers when assessing the feasibility of an RF filter project. Delays in receiving quotes from manufacturers can put clients in a challenging position, often after considerable resources have already been invested in planning.”

- David Higginson, MBA, PMP, Director of Business and Development, Q Microwave

Before finalizing a project, detailed initial design concepts, comprehensive mechanical outlines, and well-considered recommendations are provided. A comprehensive preliminary quote is also presented upfront. Once the initial design schematic for the high pass filter is reviewed and approved, the pricing and specifications for the entire project are outlined in detail.

Step 4: Manufacture the High Pass Filters

The manufacturing process for high pass filters varies depending on whether they are off-the-shelf models or customized designs. Off-the-shelf filters typically follow a standardized process, while custom filters require bespoke manufacturing techniques to meet specific project requirements.

Different materials play a critical role in the efficiency and performance of high pass filters. For instance, ceramic capacitors deliver consistent performance over a wide range of frequencies. Meanwhile, air-core inductors are commonly used in high pass filters due to their minimal core losses, allowing them to maintain low energy dissipation and a high Q factor. Surface-mount devices (SMDs) offer versatility for smaller, high-frequency applications. Each material offers unique advantages, but they also come with trade-offs, such as size, cost, or performance at specific frequencies.

When RF filter design trade-offs are necessary, the engineering team works collaboratively with customers to determine the best direction based on project priorities, ensuring all decisions are aligned with the desired outcome.

Step 5: Test and Fine Tune

How do our RF manufacturing teams test high pass filter performance? What types of tests are employed to guarantee optimal signal processing capabilities despite unpredictable environmental conditions?

Q Microwave has developed a method to replicate the cover effect for a filter, which significantly reduces lead times. Our team tests and inspects each filter individually, rather than relying on batch testing. We also implement stringent Environmental Stress Screening (ESS) techniques to validate the strength of our filter designs, including temperature cycling, vibration, burn-in, leak, and frequency tests.

How Long Does Designing a High Pass Filter Typically Take?

Lead times depend on the quantity of filters needed, the complexity of fine-tuning, and the number of sections or components required. It's important to work with a microwave filter manufacturer that maintains transparency regarding material procurement, potential trade-offs, involved processes, costs, and timelines.

Q Microwave strives to meet or exceed deadlines and quality requirements for all high pass filter designs. We also conduct satisfaction surveys after each project to continuously improve our processes, technology, and output.

Achieve Filtering Excellence with a Manufacturer that Understands Your Requirements

Quality is paramount when designing high pass filters for specialized projects, yet suppliers rarely disclose their manufacturing processes. Q Microwave has developed a reliable and transparent approach to designing high pass filters, handling every project with the highest level of precision and care. We’re always eager to share our processes and innovations with clients to build trust and ensure confidence in the results.

If you partner with Q Microwave, you’ll never have to guess “how we design a high pass filter.” You’ll have an open line of communication to discuss your project requirements and receive the support needed to achieve the best possible outcome. Contact Q Microwave today!