Additional Services

From advanced RF assembly to precision testing and product integration, Q Microwave provides full-spectrum manufacturing capabilities backed by decades of experience.

Key Products & Services

Full Service Manufacturing

At Q Microwave, we offer comprehensive manufacturing capabilities—from low-volume prototypes to high-volume production—engineered to meet stringent performance, environmental, and regulatory requirements.

Core Capabilities

- Proprietary Flexible Automated Test Software

- In House Laser Welding

- Classified Hardware and Test Capabilities

- Small Lot and High Volume Production Runs

- RF, Digital, and Environmental Screening

RF Assembly and Test Services

- High Level Material Traceability and Documentation Retention

- Efficient and Comprehensive Quality Management & Document Control Systems

Staff

- Lean “1-piece flow” Organization

- 7 Managers/Supervisors, 11 Line Leads

- 65+ Production Members

- 70% Hold Clearances

Assembly Equipment & Capabilities

- Automated PCB Inspection

- Automated Solder / Epoxy Dispensing Systems

- Automated Conduction Reflow Stations

- Automated Convection Reflow Oven

- Laser Welding, Seam Welding

- Laser Marker & Cutter

Environmental Capabilities

- Thermal Shock Chambers (5)

- Controlled Thermal Ramp Cycling

- Burn-in Fixturing & Testing for Reliability

- Leak Testing – Fine & Gross

- Vibration – Random & Sine

- Mechanical Shock

- Familiarity with Mil Standards

- IPC-A-610 Class 3

- MIL-STD-810E

- MIL-STD-883

- MIL-PRF-38534 & MIL-PRF-38535

- MIL-STD-202H

- MIL-DTL-5541

- MIL-HDBK-217F

Test & Tune Equipment & Capabilities

- Classified Testing Capabilities

- Automated Hot & Cold Testing

- Flexible Custom ATE Software with S-parameter data storage & Familiarity with

- Passband Flatness

- Insertion Loss

- Group Delay

- Isolation

- Rejection

- Compression

- IPR (Impulse Response)

- Amplitude Ripple

- Phase Ripple

- Polynomial Curve Fit

- Part Matching

- Switching Speed

- Noise Figure

- Video Transients and Leakage

- Self Generated Harmonics

- Compression

- OOB & In Band IP3

- Strong Signal Thresholding

- DC Spike Currents

- DC Ripple

- I2C, SPI, UART Communication Interfaces

- Experienced With

- Select at test tuning for precision specification setting

- RF & Digital Mixed PCB designs and testing

- Due to Q Microwave’s extensive experience with RF, DC, and Digital Testing little to no NRE is required for Test Software development.

- Dependent on the volume and level of testing required little NRE required for fixturing when ramping into production.

- Q Microwave’s practice of high detail and focus of process and procedure documentation for product specific builds reduces risk of loss of “Tribal Knowledge” over time. We pride ourselves on rigorous continues improvement to ensure knowledge gaps are eliminated.

Complex Build Example

- 26 RF Ports

- HS UART Digitally Controlled

- Temperature monitoring

- Elapsed Time

- Path Control

- Gain and Attenuation Control

- Quality Inspections

- DC Regulations Checks

- Firmware Loading

- Controls Verification

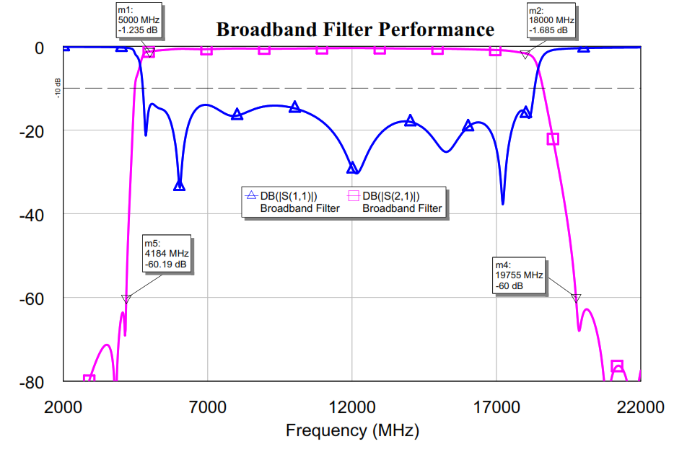

RF Filter Technology

Key Differentiators

- High-Frequency Lumped Element Filters

- Military-Grade Ceramic Resonator Filters

- Hermetic Combline Filters

- Diplexers, Triplexer, Multiplexers

Various Packaging

- Surface Mount

- Microstrip

- Leaded

- Connectorized

Integrated Module Assemblies

Key Differentiators

Cost Competitive - Lower Cost to Production

Filter Heritage allows for innovative integration of Filters

- Leads to smaller size & cost

Staff

- 5 RF Engineers

- 2 Digital Engineers

- 3 Mechanical Engineers

- 2 Manufacturing Engineers

Technologies

RF Design - AWR Microwave Office, AXIEM EM & VSS

Digital - Vivado & Quartus

Mechanical - Solidworks & Autocad

Layout - Allegro (Cadence)

RF Components

Future Developments and Releases

- Q Microwave has developed various RF Circuitry throughout its history and has gained knowledge and expertise beyond RF Filters and plans to make its precision RF Components widely available. Among some of the items that planned to be release in 2025 include:

- True Time Delay Unit – Surface mount, functional across 100MHz-4GHz with high power handling and compression points. 4 bit TTL Logic controlled.

- Receive Protect limiter for high power RF Spike control and fast recovery.

- Power combiners and dividers for broadband operation.